![]()

HG50(engage to 76) pipe making machine

1.Thesteel pipe production process: spiral steel pipe made of steel coiled coil as raw material often heated and extruded and welded by automatic double wire double-sided submerged arc welding process. 2.The characteristics of spiral stee

Send InquiryChat Now

电 话: +86-15961895852

E-mail:

sales@kehengmixing.com

Product Details

1.The steel pipe production process: spiral steel pipe made of steel coiled coil as raw material, often heated and extruded, and welded by automatic double wire double-sided submerged arc welding process.

2.The characteristics of spiral steel pipe: straight seam welded pipe has simple production process, high production efficiency, low cost and rapid development. The strength of the spiral welded pipe is generally higher than that of the straight welded pipe. It is possible to produce a welded pipe with a larger diameter by using a narrow blank, and it is also possible to produce a welded pipe of different diameter with a blank of the same width.Most of the smaller diameter welded pipes are straight seam welded, while the large diameter welded pipes are mostly spiral welded.

3.Thel tube material: Q235A, Q23b, 0Cr13, 1Cr17, 00Cr19Ni11, 1Cr18Ni9, 0Cr18Ni11Nb. Q345 L245 L290 X42 X46 X70 X80

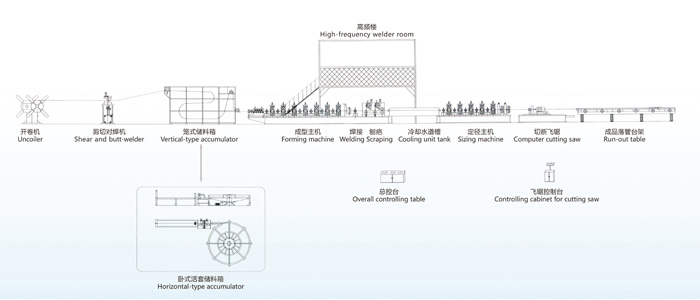

The whole lineflowchart

Raw material (steel coil) → uncoiling →material accumulating → non-power leveling →mill-forming → high-frequency welding → removing burrs outside of weld seam →zinc→ cooling → sizing → roughly straightening → fixed length cutting → run-out table

Produce Capacity

|

NO. |

Item |

Parameter |

|

1 |

Round Pipe Diameter |

Φ19mm~Φ76mm |

|

2 |

Round Pipe Thickness |

0.5mm~2.0mm |

|

3 |

Square Tube Size |

15×15~60×60mm |

|

4 |

Square Tube Size |

0.5mm~2.0mm |

|

5 |

Produce Speed |

20m/min~90m/min |

|

6 |

Length |

4m~8m |

Steel Strips Specification

|

NO. |

Item |

Parameter |

Remark |

|

1 |

Thickness of Strips |

0.5~2.0mm |

MATERIAL

Q195,235 |

|

2 |

Width of Strips |

H40~240mm |

|

3 |

O.D. of Steel Coil |

Φ800mm~Φ1500mm |

|

4 |

I..D. of Steel Coil |

Φ450mm~Φ550mm |

|

5 |

Maxi. Load Weight |

≤3000kgs |

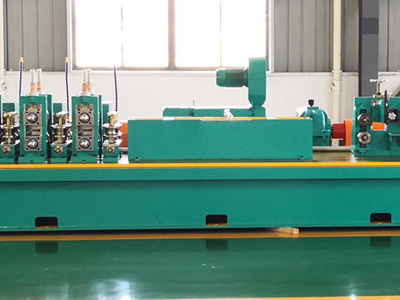

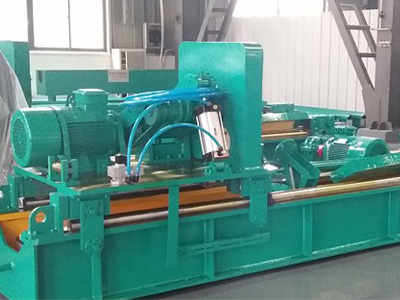

Product Picture

|

|

|

|

Double-side manual uncoiler |

Cage Accumulator |

Cage Accumulator |

|

|

|

|

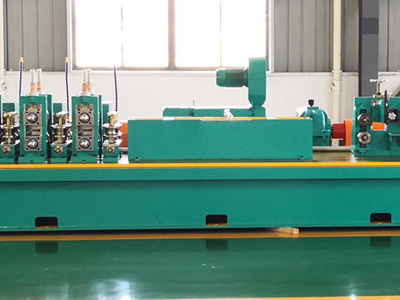

Forming machine |

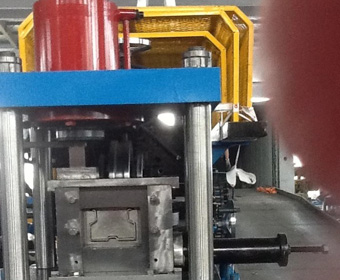

Cooling tank: Sink and shower

installed in machine bed |

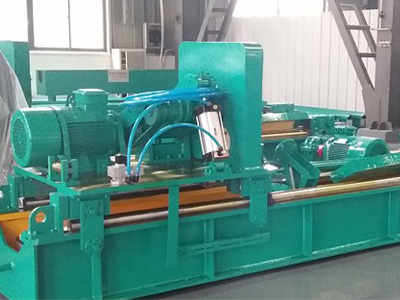

Sizing Machine |

|

|

|

|

Straightening Device |

Computer Cutting Saw |

Single Side Run-out Table:

The function is to convey the finished pipe after cutting |

Other Products

Product Advantage

1.Technological process of the production line is concise, compact layout, advanced technology, put an end to produce defects, comprehensive energy consumption is low, simple operation and maintenance, low operating cost.

2.Production line adopts the standard electrical, instrumentation components and equipment components meet the needs of the buyers,Control system has the maintainability and expansibility; And ensure the advanced technology, reliable control, during normal operation can automatic complete all real-time detection and adjusting function, have interlocking function to prevent wrong operation, Do all the operation, monitoring on main operating platform .Display and handle the alarm.

Company Profile

Wuxi HRF Science & Technolog Co.,Ltd located in Wuxi city,Jiangsu province which is close to Shanghai international airport ,we enojoy convenient transportation and advantageous location with which supply good business opportunities for the investors home and abroad.And our company was established in 2009, has the specialized technical team, provides the high quality product and the high quality service for you.

Our company are specialized in designing,manufacturing,sales and services in the field of cold roll forming machines, we can supply the stud-track forming machines,c/z purlin forming machines,roof &wall forming machines,expressway guardrail forming machines, metal deck forming machines ,steel tile forming machines ,PU sandwich panel production line as well as slitting lines and cut-to-length machines lines and so on.

"Copra" software made in Germany is a kind of professional software for designing the cold roll forming machines.In the past years,we devoted ourselves to studying,training and putting into production.Through continous efforts made by our staffs,we already improved a lot on the machines quality and won good repution in the worldwide.

We are ready to establish the business relations with the overseas customers and we also believe" the oppotunity here,here you are"

Our commitment is quality and service , our goal is customer satisfaction . We will, as always, be pragmatic and promote mutually beneficial cooperation and common development Of you

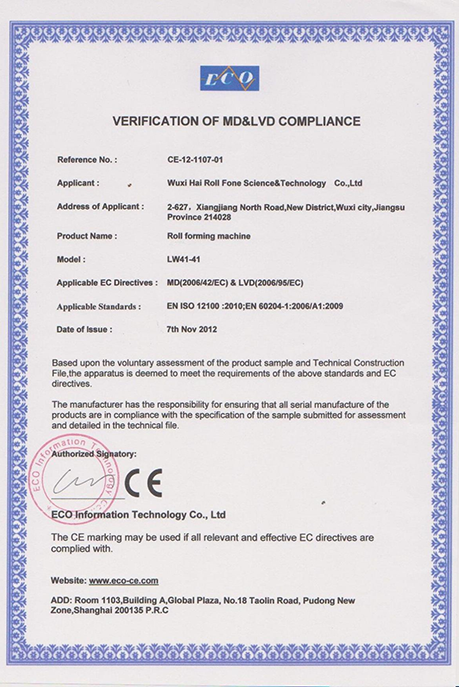

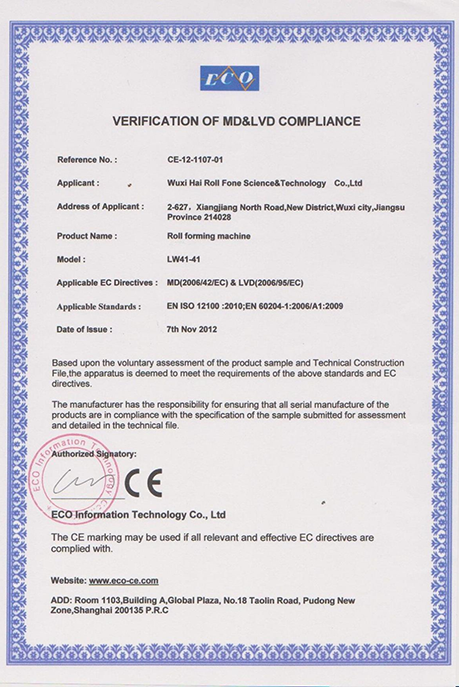

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

3. What is the quality of your machine?

The first class Quality. We manage to offer our partners the best customer care, products and services by using the latest technologies in the branch. The components we provide are of best quality, to make sure our machines can be running very well for decades.

4. What service we can get from your company?

-VIP Service. Due to our standards, we manage to build long-lasting relationships with all our customers. We are 24/7 online available for you to answer your questions and solve your problems.

5. Quality Inspection

The machines of our company have many certificates like ISO 9001, CE, SGS, etc. Before the shipping, we have a series of quality check system, includes 3 times of inspection for every production procedure. First inspection needs the workers to check and sign on the test report. Second inspection involves department leaders to check and sign on the test report. The Third inspection needs professional inspector to check and ensure the machines are qualified. We also give 18 month warranty time to the customer

Related Products

TEL: +86-510-81153870

TEL: +86-510-81153870

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.