TEL: +86-510-81153870

TEL: +86-510-81153870 Email: info@wxhrf.com

What’s the sitting machine? Main function? Classification?

1.What's the slitting machine? Slitting machine is also known as slitting line, is a metal slitting equipment, According to customer requirements, the deferent material coil will be lengthwise cut into a number of required specifications strip.

2.What’s the main function? Slitting machine is suitable for longitudinal shearing of metal strip and rewinding narrow strip after cutting. The smaller metal strips are recoiled at the end of the slitting machine by which these smaller strips are used necessarily for the next process usage in the professional field of making transformers,motors making industry,tube/pipe welding mill industry,Cold roll forming industry, ceiling drywall industry and other high-precison equipment making and metal strips making industries.

3.What’s the classification? According to the material slitting thickness there are thin plate or board slitting machine,media-thickness plate or board slitting machine and thick plate or board slitting machine. According to the metal materials there are copper strips slitting machine,stainless steel slitting machine,cold or hot rolled plate slitting machine,silicone steel slitting machine.

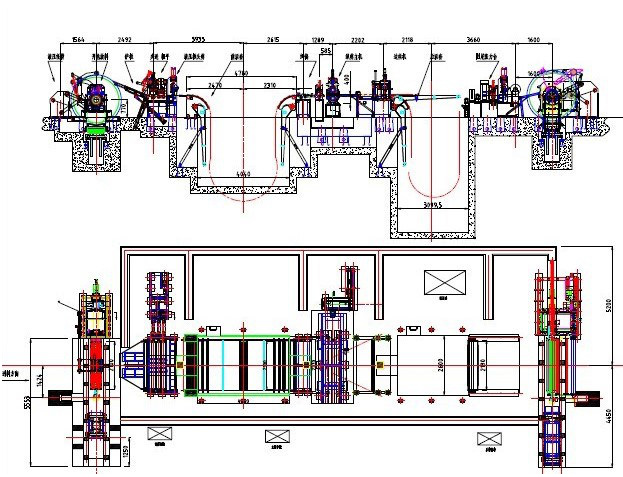

The whole lineflowchart

Coil loading car----Decoiler----loop pit 1-center aligner-----slitting machine--waste scrap winder- loop pit 2--pre-separator--tensioner---pressing separator--recoiler--manual packing-Unloading coil car

Shearing Data

| Item | material thickness/mm | Material width | speed/mpm |

| 1 | 0.2-2 | 400-2000 | 0-50-80-100-150 |

| 2 | 0.3-3 | 400-2000 | 0-50-80-100-120 |

| 3 | 0.4-4 | 500-2500 | 0-50-80-100-120 |

| 4 | 0.5-5 | 500-2500 | 0-50-80-100-120 |

| 5 | 1.0-6 | 500-2500 | 0-50-80-100 |

| 6 | 2.0-8 | 500-2500 | 0-30-50 |

| 7 | 3.0-10 | 800-2500 | 0-30-50 |

| 8 | 4.0-12 | 800-2500 | 0-30-50 |

| 9 | 8-16 | 800-2500 | 0-30-50 |

| 10 | 6.0-20 | 800-2500 | 0-30 |

Components of the whole line

| No. | Name | Quantity |

| 1 | Coil car | |

| 2 | Double-mandrel decoiler | |

| 3 | Coil-head-feeding & shoveling | |

| 4 | Double pinch rolls &5-rolls leveling | |

| 5 | Head-cutting | |

| 6 | Hole accumulator | 1 set |

| 7 | Strip-aligning unit | |

| 8 | Main slitting machine | |

| 9 | Scrap reeling unit | |

| 10 | Hole accumulator | 2 sets |

| 11 | Pre-separator/Tensioner | |

| 12 | Separator & Recoiling | |

| 13 | Coils-dischargin car |

Basic specification of the steel coil:

1 Steel coil material:common carbon steel,galvanized steel or pre-painted steel

2 Coil thickness:0.3mm--3mm

3 coil diameter:max 2100mm

4 Coil width500mm---1600mm

5 Coil inner diameter:≥508

6. Coil weight:max 20T

Technical specifications of the complete slitting machine:

1 The Material of available coils: apply for carbon steel ,cold rolled or hot rolled steel ,galvanized steel coil

2Thickness of the coils: 0.3—3mm;

3Width of the slitting coils:max 1600mm

4.Precision of slitting width tolerance: ±0.03mm

5.Slitting speed: 0—80m/min(adjustable)

6.Loading capacity of uncoiler machine:20T

7.Coil Inner.Diameter: 460mm-610mm-760mm

8.Coil Outer.Diameter: max 2100mm

9.Slitting motor power:75kw DC motor

10.Recoiler motor power:90kw DC motor

11.Slitting blades:D205mmxd305mmxT15

12.material of the slitting blades:Cr12Mov(SKD-11),Hardness of blade: HRC58°—60°

13.Min slitting width : ≥30mm

14.Slitting blade quantity: 22 pcs

15.Recoiler I.D: ф508mm

16.Power supply: 380V 50Hz,3Ph or 440V,60Hz,3ph

17.Total dimension:25mx6mx2m

17.Total consumption:200kw

|

|

|

|

|

|

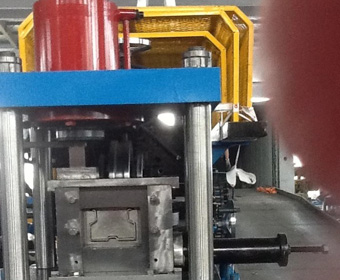

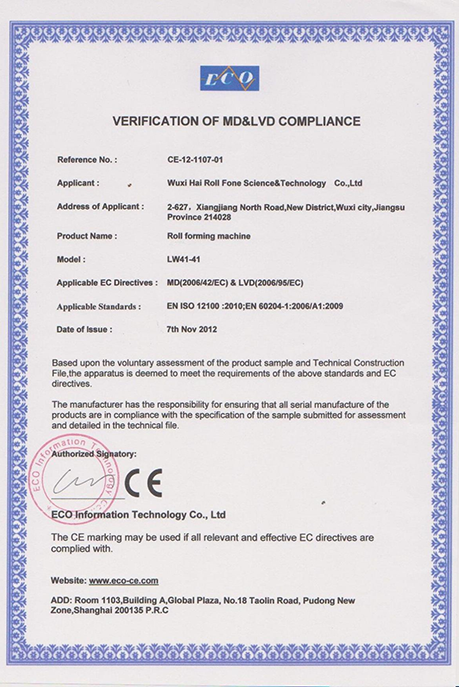

Certified product

Certified product

Customer Photos

Customer Photos

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.

FAQ

1. Why should you choose from us?

Professionalism. We are a professional manufacturer in Slitting & Cut to Length (CTL) line machine for more than 20 years. We can provide cost-effective & high quality slitting and cut to length machines. So far we have exported to more than 80 countries, including Argentina, Bangladesh, Belarus, Bolivia, Brazil, Chile, Egypt, Indonesia, Iran, India, Malaysia, Pakistan, Philippines, South African, Turkey, Russian, UAE, Saudi Arabia, Vietnam, etc. Our dedicated sales &technology &service team of specialists is always customer-oriented.

2. How about the safety ?

We exclusively collaborate with specialists in cargo safety and our suppliers are chosen for their promptness and high standards. We have our own professional staff to tied the machines firmly to the inside of container by steel rebar. We always deliver the machines on time and keep the customer well informed about the shipping information and drawing.